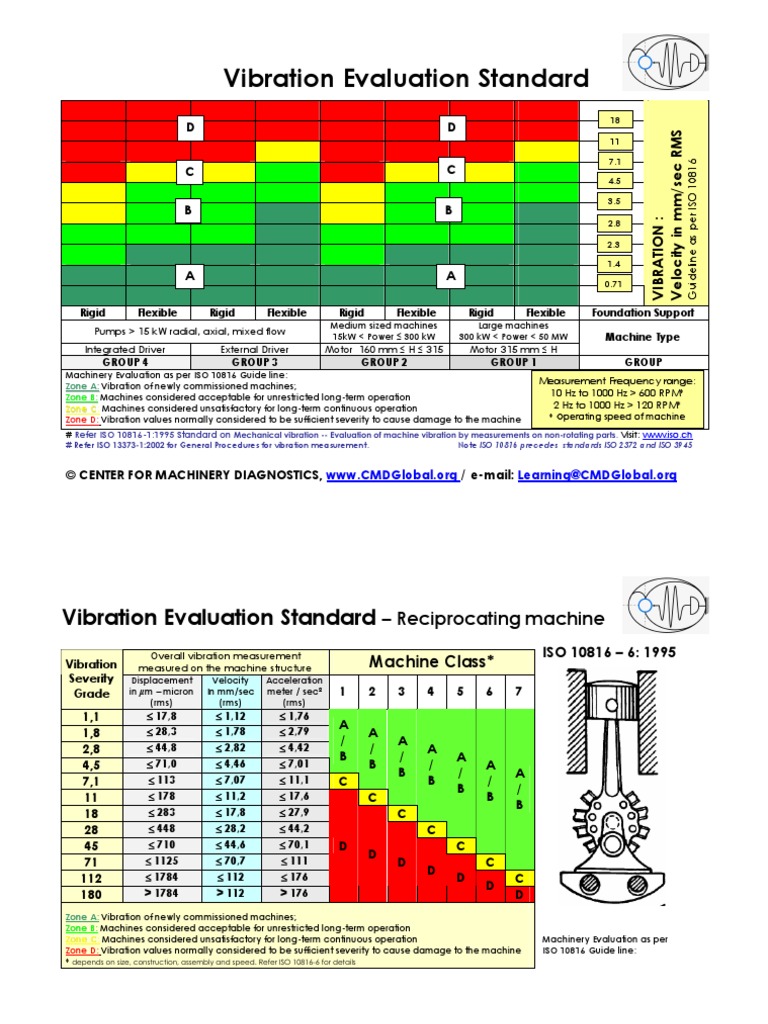

ISO 10816 Vibration Severity Standards ISO 2372 (10816) Standards provide guidance for evaluating vibration severity in machines operating in the 10 to 200Hz (600 to 12,000 RPM) frequency range. ISO 10816-3 defines four groups of machines, ranked according to size, base and purpose. It separates the working conditions into four zones: Monnit’s Standard Vibration sensor (with a frequency range of 10 to 200 Hz and vibration range from 0 to 600 mm/s (¹) is well suited to measure systems identified by ISO. ISO 10816-3 was prepared by Technical Committee ISO/TC 108, Mechanical vibration, shock and condition monitoring, Subcommittee SC 2, Measurement and evaluation of mechanical vibration and shock as applied to machines, vehicles and structures. This second edition cancels and replaces the first edition (ISO 10816-3:1998). The main change is the. Permissible exposure limits for vibrations are established by entities such as the International Standards Organization (ISO). ISO vibration regulations include: - DIN ISO 10816 (vibration severity in machines) - DIN ISO 7919 (mechanical vibration) - DIN 4150 (structural vibration, buildings) - DIN ISO 10816-3 (machine condition, machine. ISO 10816-3 Standard for vibration severity. For Designing of machine condition monitoring system using fuzzy logic in LabVIEW, a set of hypothetical data is used. The system consists of single input and single output. The values that serve as the input data for the system is stored using the Microsoft Excel Program.

Evaluation of machine vibrations based on DIN ISO 10816-3

The scope of this standard includes steam turbines up to 50 MW, electric motors and fans. Because the scope is quite wide, the standard is explained in more detail below. The standard aims to classify the machine state in four different classes by means of vibration data for acceptance measurements and operational monitoring.

Assessment criteria according to the standard are the RMS value of the vibration velocity and the RMS value of the vibration displacement. Usually it is sufficient to measure the vibration velocity. The additional evaluation of the vibration displacement is recommended if low frequency components are encountered. If both vibration parameters are logged and analyzed, the poorer of the two determined classes is applied.

The frequency range of the vibrations to be captured depends on the machine speed:

- 10 Hz to 1000 Hz for speeds of more than 600 rpm

- 2 Hz to 1000 Hz for speeds of less than 600 rpm

Iso 10816 1

Suitable measuring points are characterized by the fact that they reflect the dynamic forces of the machine as purely as possible. For example, locations where local resonances occur are not suitable. Suitable locations tend to be bearing stands and bearing covers; measurements are usually carried out in two orthogonal directions.

The classification also takes into account the machine substructure, subdivided into rigid and elastic substructures. If the lowest natural frequency of the whole system consisting of machine and substructure is at least 25% higher than the main exciting frequency (generally the rotational frequency), the substructure can be regarded as rigid, otherwise as elastic. This evaluation should be carried out separately for each measuring direction (two orthogonal directions, see above).

Vibration Standard Iso 10816-3 Pdf Free Download

DIN ISO 10816-3:2009 describes four evaluation zones (A, B, C, D), with limit values as listed in the following table.

Vibration Standard Iso 10816-3 -

Machine group | 1 | 2 | |||

Installation | rigid | elastic | rigid | elastic | |

RMS value of the vibration velocity in mm/s | 11,00 .. ∞ | D | D | D | D |

7.10 .. 11.00 | D | C | D | D | |

4.50 .. 7.10 | C | B | D | C | |

3,50 .. 4,50 | B | B | C | B | |

2.80 .. 3.50 | B | A | C | B | |

2.30 .. 2.80 | B | A | B | B | |

1.40 .. 2.30 | A | A | B | A | |

0.00 .. 1.40 | A | A | A | A | |

Machine group | 1 | 2 | |||

Installation | rigid | elastic | rigid | elastic | |

RMS value of the vibration displacement in µm | 140 .. ∞ | D | D | D | D |

113 .. 140 | D | C | D | D | |

90 .. 113 | D | C | D | C | |

71 .. 90 | C | B | D | C | |

57 .. 71 | C | B | C | B | |

45 .. 57 | B | B | C | B | |

37 .. 45 | B | A | B | B | |

29 .. 37 | B | A | B | A | |

22 .. 29 | A | A | B | A | |

0 .. 22 | A | A | A | A | |

Zone A | The vibrations of recently commissioned machines tend to be in this zone. |

Zone B | Machines with vibrations in this zone are usually regarded as suitable for continuous operation without restrictions. |

Zone C | Machines with vibrations in this zone are usually regarded as unsuitable for continuous operation. The machine may generally be operated in this state for a limited period, until a suitable opportunity for remedial measures arises. |

Zone D | Vibration values in this zone are usually regarded as dangerous in the sense that damage to the machine may occur. |

Machine group 1 | Large machines with a rated output of 300 kW to 50 MW and electrical machines with a shaft height of more than 315 mm |

Machine group 2 | Medium-sized machines with a rated output of 15 kW to 300 kW and electrical machines with a shaft height between 160 mm and 315 mm |